Method 319 Compliant System

The National Emission Standards for Hazardous Air Pollutants (NESHAP) sets specific standards, tests, and procedures for aerospace manufacturing and rework facilities. AULNAY provides several filtration options to help you comply with NESHAP regulations. Our filters are designed to meet the EPA's Method 319 test protocol.

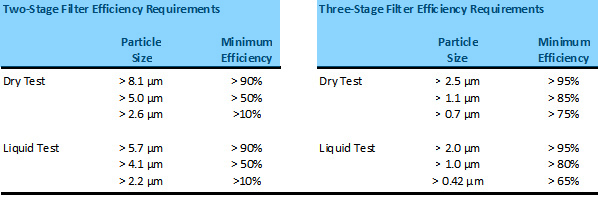

Method 319 (EPA) uses potassium chloride and oleic acid in place of chromate paint. These substances simulate the dry and wet overspray characteristics of chromate paint, ensuring an air filtration system meets the minimum efficiency requirements in laboratory conditions.

For all operations in a spray booth or hangar:

- Air flow should be downward or across the part and exhausted through a control device;

- A control device can be a dry particulate filter (also known as a paint arrestor), but it must meet certain minimum standards.

In this way, we can ensure compliance with NESHAP regulations while maintaining the quality and performance of the air filtration system.

The tables below show the required compliance efficiency levels by micron size.

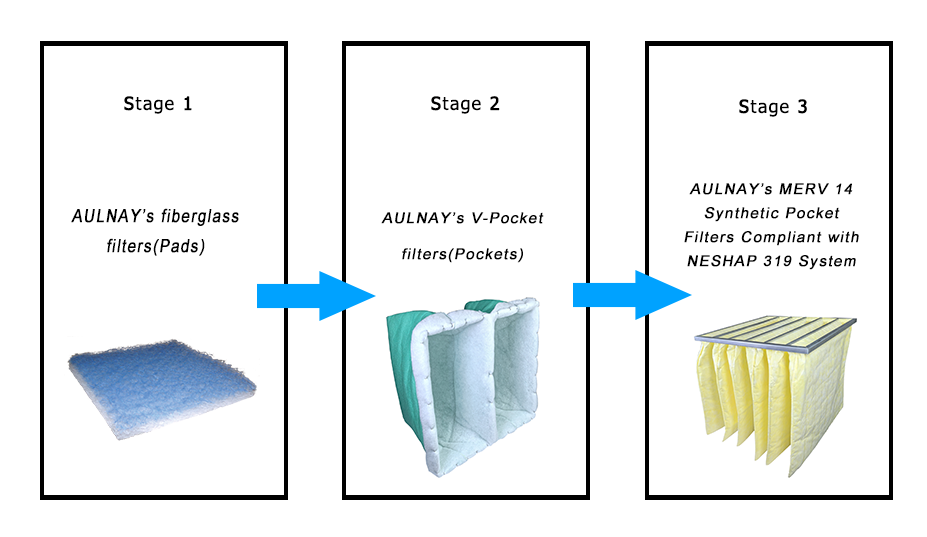

Three-Stage NESHAP Filtration System

The Environmental Protection Agency (EPA) has devised a test protocol named Method 319. This protocol is utilized to ascertain whether a dry particulate filter or filter adheres to the National Emission Standards for Hazardous Air Pollutants (NESHAP). Method 319 endeavors to mimic the dry and wet overspray traits of both hazardous air pollutants (HAPs) and volatile organic compounds (VOCs), thereby providing a standardized means of evaluating the performance and compliance of the filters in question.

Paint systems installed after October 29, 1996 require a 3 - stage filtration process similar to the one depicted below.